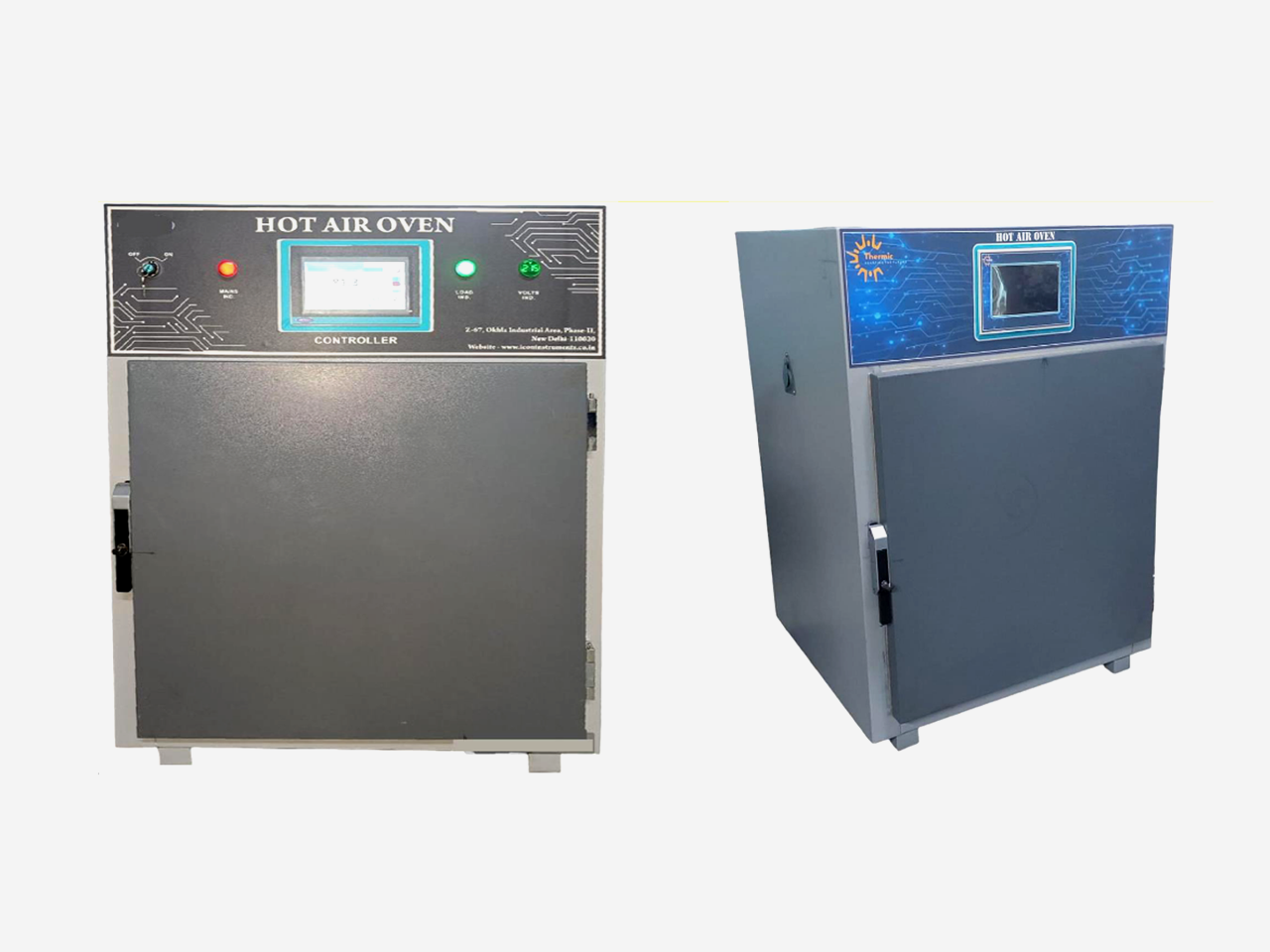

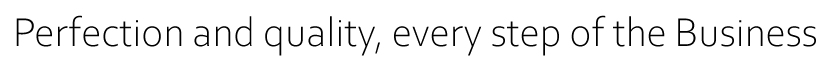

TEMPERATURE CONTROL :

Thermic hot air ovens are equipped with precise temperature controls,

typically managed by digital thermostats or controllers. This feature

ensures accurate and consistent heating for a wide range of applications.

CIRCULATION SYSTEM:

THERMIC Hot Air Oven oven is designed with a fan or an air circulation

system to maintain even temperature distribution throughout the chamber.

This uniform heating is crucial for achieving reliable and reproducible

results.

INSULATION:

Hot air ovens are well-insulated to minimize heat loss and improve energy

efficiency. Insulation materials such as glass wool or other thermal

barriers help maintain a stable internal temperature.

INSULATION:

Mineral wool / Blanket Insulation to keeps the surface of the instruments

from not being burnt.

HEATER:

Best quality coil shaped heaters duly embedded / wound on the sides &

bottom for better accuracy, MOC of Heater should be ferritic

iron-chromium-aluminium alloy (FeCrAl alloy) for high temperatures. The

alloy is characterized by high resistivity and good oxidation resistance.

DESIGN:

It should have ventilation to keep the surface of the instrument from being

not been burnt even when the instrument maintained at high temperature.

TEMPERATURE CONTROLLER:-

HMI Display with Feather Screen Touch Digital Temperature Controller, Screen

Size 7” Display Continuous display of Temperature, Time, Day & Date

Door Open Alarm, HMI Display of Data & Graph

- Password Protected

operations,

- Data transfer

port: USB port

- Data log/Memory:

- Door Open Alarm,

- Programmable

- Power Consumption: 220/230V AC± 10%, AC Supply Single

Phase 50Hz

- Safety Function: Temperature Over

- Duty Cycle: Continuous